Category Archives: QC Electronics Blog

Metal Surface Treatment

Metal surface treatment is a crucial process that enhances the adhesion, durability, and performance of [...]

What is Bump Treating?

The process of converting raw materials into finished products involves several stages, including web handling [...]

Custom Corona Treaters for Unique Applications

Are you struggling to find a corona treater that can handle your unique application or [...]

Surface Modification with Corona Treatment

When we want to stick two things together, sometimes it can be difficult to get [...]

Corona Treating: What is Overtreatment and Plasma Etching?

Overtreatment can be costly to your company and product. It is easily avoided following the [...]

Corona Treater Maintenance

As with any industrial equipment, a good maintenance schedule helps extend the lifespan of the [...]

The Truth about Dyne Pens

Attending industry trade shows has given me a lot of insight into the printing industry [...]

Basics of Web Corona Treaters

Surface treatment definition: “The modification of the surface to increase surface tensions resulting in better [...]

Corona Treatment Lab for Printing and Adhesion Advice

QC Electronics has established an elite corona treatment laboratory for the corona treatment of samples, [...]

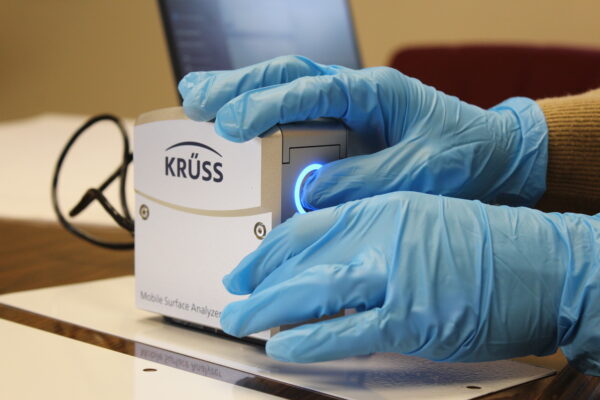

Dyne Testing Procedure

Follow this procedure to ensure successful dyne testing polymer substrates. What you will need: Safety [...]