Attending industry trade shows has given me a lot of insight into the printing industry and the lack of knowledge in achieving a guaranteed bond. My experience in manufacturing has shown that small errors can lead to excruciating losses. The misunderstanding and mismeasurement of characteristics required for a guaranteed bond is one of those dangerous errors.

Dyne solution was formulated for PET. Therefore, should only be used with PET. Unfortunately, this information is not widely known. Dyne solution has long been an ‘industry standard’ as an easy way to find out if the surface energy of the material is compatible with the adhesive. This causes a misunderstanding of the surface’s true bonding characteristics, and in result, detrimental losses.

Dyne solution is not a controlled measurement. It is exposed to air and other outliers, like the materials it is applied to and human error, every time a measurement takes place. These outliers impact the accuracy of the test. I’d also like to emphasize again:

Dyne solution was not formulated for use on all materials, but only PET.

Effective surface treatment validation requires accuracy. Unfortunately, in an industry where dyne solution testing is the standard, error-free surface treatment validation is often not the case. But – good news – it can and does exist.

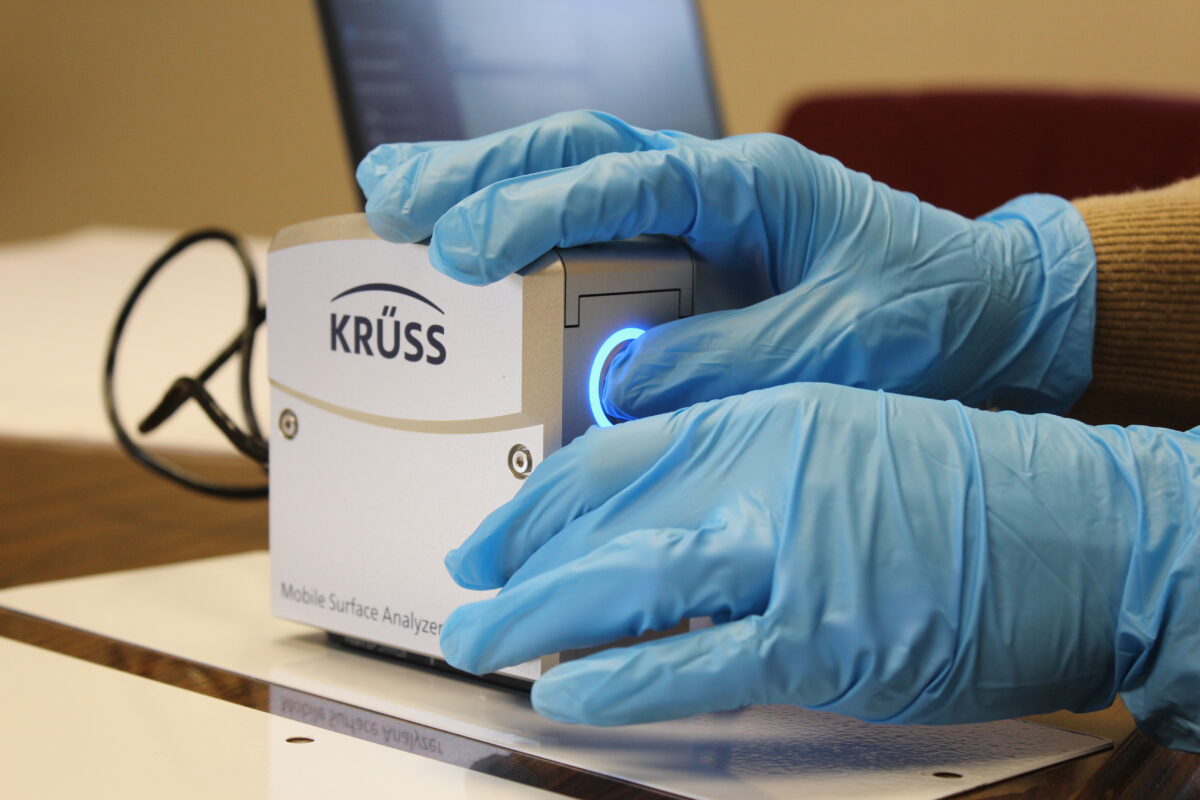

QC Electronics uses a mobile surface analyzer to conduct all tests. This small machine collects and stores data with error-free measurements. It uses the contact angle measurement method. It drops two droplets, water and diiodomethane, and measures and records each droplet’s reaction to the material. Thus, providing an error-free, accurate surface energy reading. This allows people to guarantee their bond and remove the painful – and costly – trial and error process of new applications.

By removing outliers that cause failures in test accuracy, the MSA ensures a pass/fail validation every time.