compare

Smart Performance Regulation

Automatically adjusts key parameters in real time to maintain consistent treatment quality and maximize efficiency.

touch_app

Live System Feedback & Data Logging

Monitor operations in real time while automatically logging key performance data for traceability and analysis.

verified_user

Adaptive Watt Density Control

Ensures precise watt density levels are maintained throughout operation, optimizing performance and reducing human error.

nest_remote_comfort_sensor

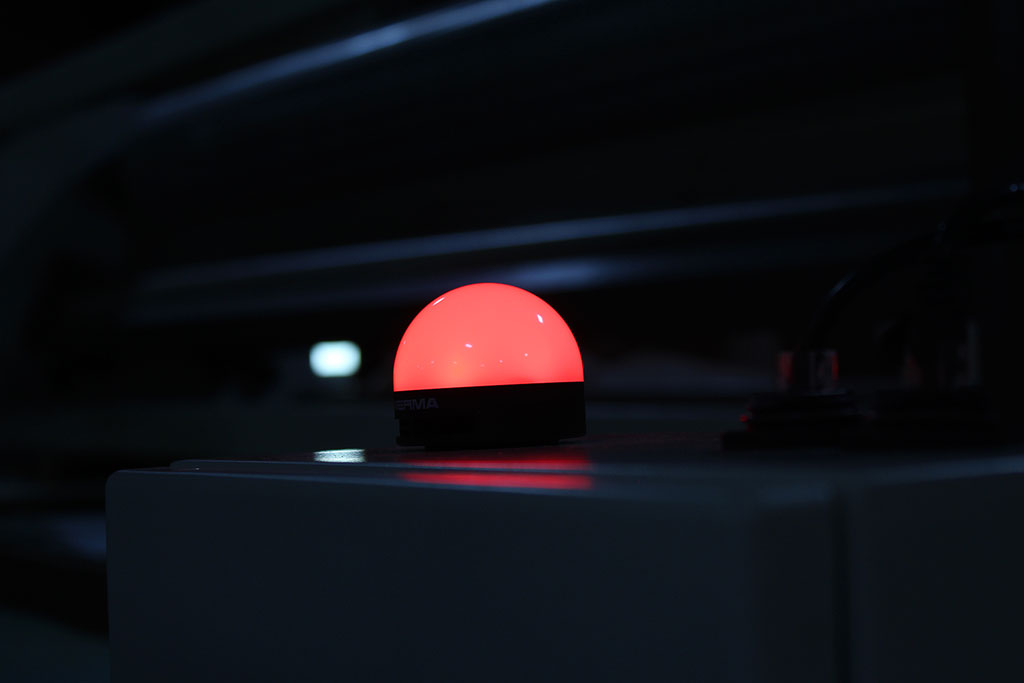

Centralized Control Center

Manage all system parameters, diagnostics, and settings from one intuitive interface.

tune

Customizable Control Logic

Configure control settings and automation rules directly from the interface.

integration_instructions

Press Control Integration

Supports both Fieldbus protocols and discrete I/O for flexible connectivity with existing control systems.