What is Corona Treatment?

Corona treatment is a process used to improve the adhesion of inks, coatings, and adhesives to plastic films and other materials. It works by applying a high-voltage electrical discharge to the surface, which increases its surface energy. This makes the material more receptive to bonding, ensuring that inks and coatings stick better and last longer.

Benefits of Corona Treatment

- Improved Adhesion: Corona treatment enhances adhesion for printing, coating, and laminating.

- Increased Surface Energy: Substrates that are corona treated experience an increase in surface energy, which improves wettability and bonding.

- Versatility: A wide range of materials can be corona treated.

- Cost-Effective: Corona treatment can be a cost-effective solution when compared to other treatments.

- Environmentally Conscious: Corona treatment is safer for the environment than chemical coatings used to prepare substrates for bonding.

Equipment

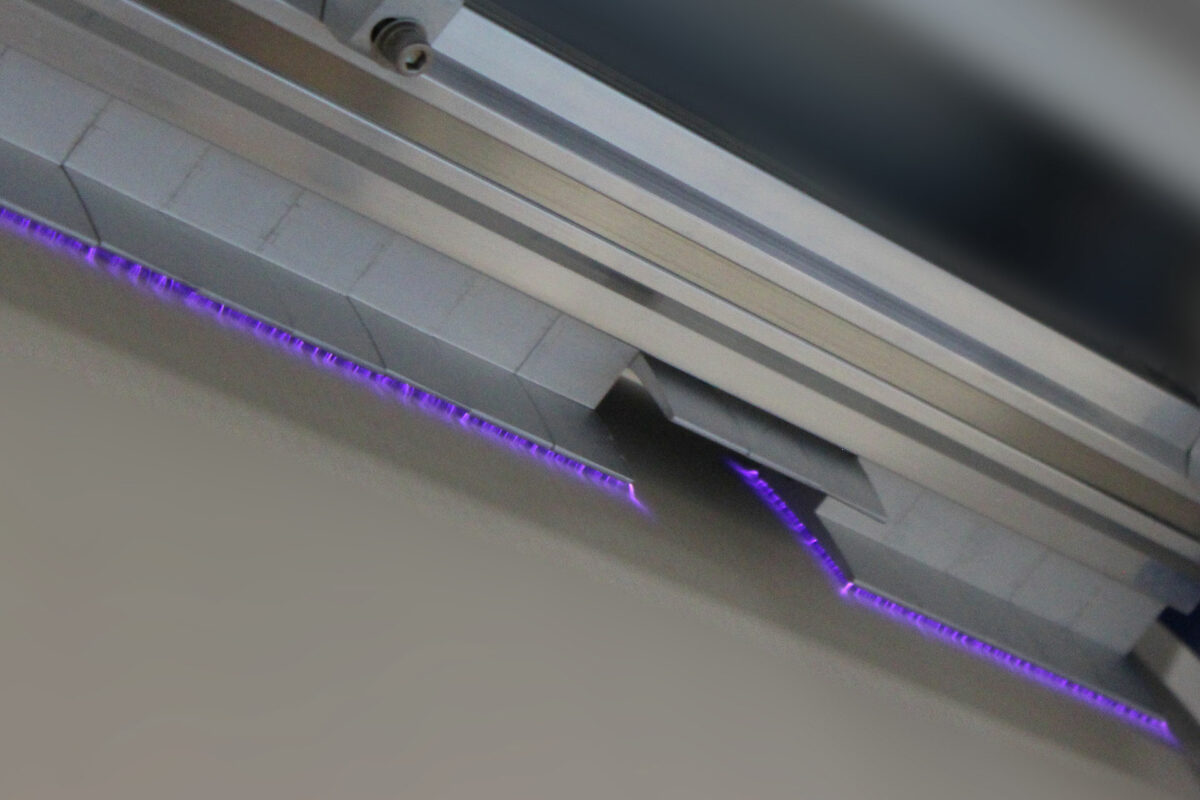

The line consists of an unwind/rewind with advanced web handling, a QC Advantage corona treatment system for any substrate (conductive or nonconductive) and a QC TNT Touch N’ Treat corona treatment system for nonmetallized (nonconductive) substrates.

get a quoteCapabilities

- Widths up to 60″

- Single or double sided treatment

- Up to 24″ diameter rolls

- Any conductive or nonconductive film

More Information

Being corona treater OEM, we have corona treated a vast range of materials. With a large database, we deliver results on the first try. The most commonly corona treated films are listed but not limited to:

Polyethylene (PE) Films

Low-Density Polyethylene (LDPE): Widely used in packaging films, shrink films, and agricultural films.

Linear Low-Density Polyethylene (LLDPE) Films: Used in stretch films, agricultural films, and packaging films due to their flexibility and strength.

High-Density Polyethylene (HDPE): Common in packaging, grocery bags, and liners.

Polypropylene (PP) Films

Biaxially Oriented Polypropylene (BOPP): Used in packaging, labeling, and printing.

Polyethylene Terephthalate (PET) Films: Used in food packaging, medical packaging, and as a substrate for solar panels and electronic displays.

Polyvinyl Chloride (PVC) Films: Utilized in shrink sleeves, flexible packaging, and certain industrial applications.

Polystyrene (PS) Films: Common in food packaging and other applications requiring clarity and stiffness.

Polyamide (Nylon) Films: Used for food packaging, particularly for products requiring high barrier properties.

Thermoplastic Polyurethane (TPU) Films: Employed in protective films, medical devices, and flexible electronics due to their elasticity and durability.

Polylactic Acid (PLA) Films: A biodegradable option used in food packaging, labels, and agricultural films.

Ethylene Vinyl Alcohol (EVOH) Films: Known for superior gas barrier properties, used in food packaging to protect from oxygen.

If we listed all the films that can be corona treated, we’d bore you. If you don’t see your film on this list, ask us about it.

- Packaging (food, medical, industrial)

- Printing (labels, graphics)

- Coating (protective, decorative)

- Laminating (multi-layer packaging, barriers)

- And more!

- Consultation: A QC representative collects necessary application details and provides recommendations on best practices, and best treat levels for your specific application’s success.

- Treatment: The line is set up per substrate and application requirements. Target dyne level and surface energy is set, and watt density is confirmed to delivery precise treatment results.

- Quality Control: Corona treatment is tested with MSA (mobile surface analyzer) to verify results are as expected. Corona treated material is then packaged to protect and prepare corona treated material for shipment.

- Delivery: Expect a 1–2-week turnaround.