Choosing the Right Corona Treater

Selecting the right corona treater for your process depends on your material type, application, and line configuration. Understanding the difference between bare roll and covered roll corona treaters is key to choosing the best web corona treater for your company’s offering.

let us help youAdvantage Corona Treater

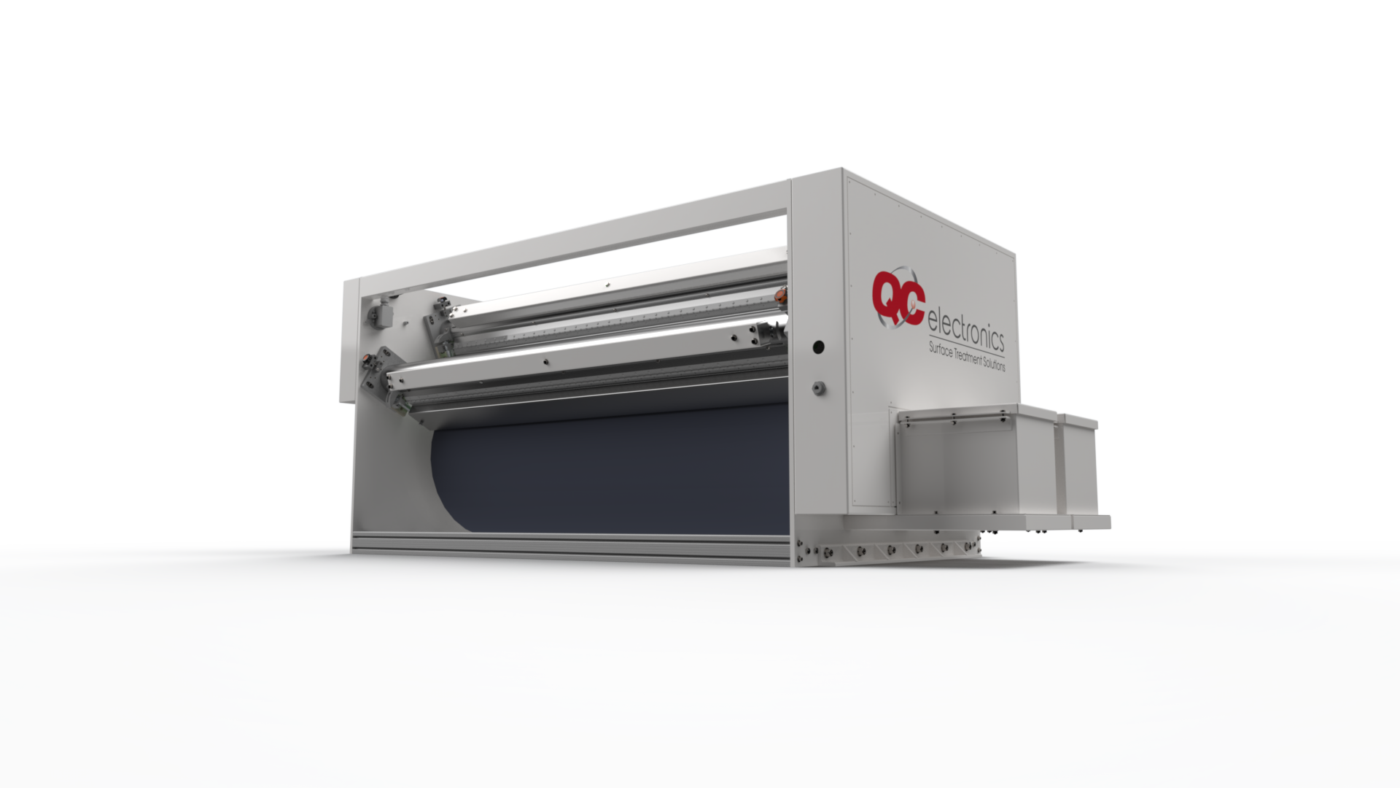

The Advantage corona treater can treat both metallized and nonmetallized substrates. Commonly installed on flexo and rotogravure presses. A great tool in printing, laminating and coating processes.

see the advantageWho should buy a bare roll corona treater?

- Converters with a wide range of materials to treat.

- People who desire versatility.

TNT Corona Treater

The TNT is for nonconductive (nonmetallized) substrates only. Commonly installed on blown and cast film lines. The TNT is more efficient for treating nonconductive substrates than the Advantage due to its unique electrode.

see the tntWho should buy a covered roll corona treater?

- Blown and cast film extruders.

- People who only corona treat nonconductive materials.

Benefits of Installing a QC Web Corona Treater

Investing in a QC web corona treater provides you with the benefits of high production power with low downtime and maintenance requirements.

High Production Output

Our web corona treaters are designed to handle high-speed production lines, ensuring maximum output without compromising quality.

Minimal Downtime

With our advanced technology and robust design, our corona treaters require minimal downtime, reducing costly interruptions to your production process.

High Power and Efficiency

Our corona treaters feature cutting-edge technology that provides high power and efficiency, resulting in superior surface treatment and improved adhesion and printability.

Integration

Our corona treaters are designed to seamlessly integrate with any new or existing production line, making it a flexible solution for your surface treatment needs.

find the perfect match

Let the experts do the work.

We request all the important details and more to deliver a corona treater that is perfectly suited for your needs.

start nowHigh Production – Low maintenance

The Best Features

Intelligent

The advanced interface allows operators to finetune their desired treatment settings and monitor the treater’s performance. The touch panel interface is highly intuitive and user-friendly, providing operators with the ability to quickly and accurately adjust treatment parameters as needed.

Easy Threading & Maintenance

The counter weighted swinging electrode assembly provides unobstructed access for threading and maintenance. This feature ensures a hassle-free process that saves time and effort, allowing your operators to focus on other critical aspects of your production process.

Cool Operation

Unlike traditional corona treaters that generate a lot of heat during operation, our advanced technology is designed to minimize heat buildup and reduce the risk of overheating.

Unique Power Supply

The SCR technology in our power supply provides a more stable and consistent power output, resulting in improved surface treatment and higher production rates.

Splice Detection

Our innovative design includes sensors that detect splices and work with the pneumatics to automatically swing and stop the electrode assembly, reducing the risk of web breakage.

Proprietary Technology

While we can’t reveal all the details, we can say that our technology involves a unique approach to corona treating that optimizes power output and improves treatment performance.

Free Samples

With our state-of-the-art corona treaters and expertise, you can trust that your materials will receive the most fine-tuned results per your application. Contact us today to request samples.

get startedour promise

Guaranteed Performance

bolt

Surface Energy

QC customers have peace of mind knowing that their materials will adhere properly and consistently.

sticky_note_2

Adhesion

We utilize state-of-the-art testing equipment and techniques to ensure the most accurate and reliable results.

support

Support

Rapid response times, expert technical support, and ongoing training and education for customers.