Corona treatment is a surface modification process that uses a plasma and flame corona field to increase a material’s surface free energy and wettability thus increasing adhesion. The wettability of your material is important when bonding, coating, or printing.

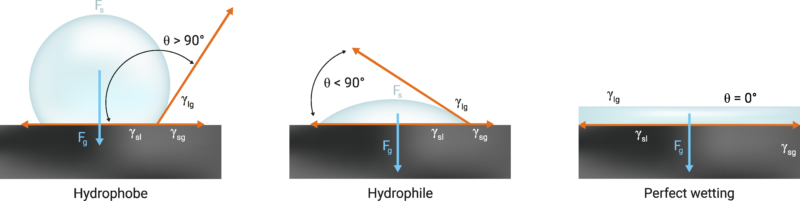

What links surface free energy and wettability you ask? Think about it this way. Liquids take up the smallest possible surface area; we have all seen a water spill on a hard surface – if you watch it, it forms into balls once it encounters the surface (changing its shape to take up the least amount of surface area). Solids cannot change their physical form, but they can form an interface with a liquid to reduce its free energy (they can be wetted). Thus, the surface free energy of a solid is directly related to its wettability. See the diagram below for a clear illustration of wettability. When perfect wetting is achieved, the ink will adhere to the material perfectly, with no smudging or residue left behind when wiped.

Each material reacts to treatment differently, which is why it is important to understand your material when considering corona treatment. Luckily, we possess the knowledge to assist you in this process.

In 2021, QC has heavily invested in our in-house laboratory. We now have the capability to measure the wetting before and after corona treatment with our new contact angle measurement equipment in addition to dyne testing. If you are interested in having sample services done, please contact sales@qcelectronics.com. We look forward to working with you.

Follow us on LinkedIn to stay up to date with new products and announcements in corona treating.